The food processing industry requires efficient and reliable pumping solutions to ensure product quality and safety. Rotary lobe pumps are an excellent choice for food processing applications due to their gentle product handling, high efficiency, and ease of maintenance.

Benefits of Rotary Lobe Pumps in Food Processing

- Gentle Product Handling: Rotary lobe pumps handle sensitive products gently, reducing damage and ensuring product quality. This is particularly important in food processing applications where product integrity is crucial.

- High Efficiency: Rotary lobe pumps are highly efficient, reducing energy costs and increasing production capacity. They can handle a wide range of viscosities and flow rates, making them versatile for various food processing applications.

- Ease of Maintenance: Rotary lobe pumps are easy to maintain, reducing downtime and increasing overall efficiency. They have fewer moving parts than other types of pumps, which reduces wear and tear and minimizes the need for repairs.

Read more: Rotary Lobe Pump

Applications of Rotary Lobe Pumps in Food Processing

- Sauces and Dressings: Rotary lobe pumps are ideal for transferring viscous sauces and dressings, such as ketchup, mayonnaise, and salad dressings.

- Dairy Products: Rotary lobe pumps can handle dairy products, such as milk, cream, and yogurt, with ease and efficiency.

- Beverages: Rotary lobe pumps can be used in beverage production, including juice, wine, and beer.

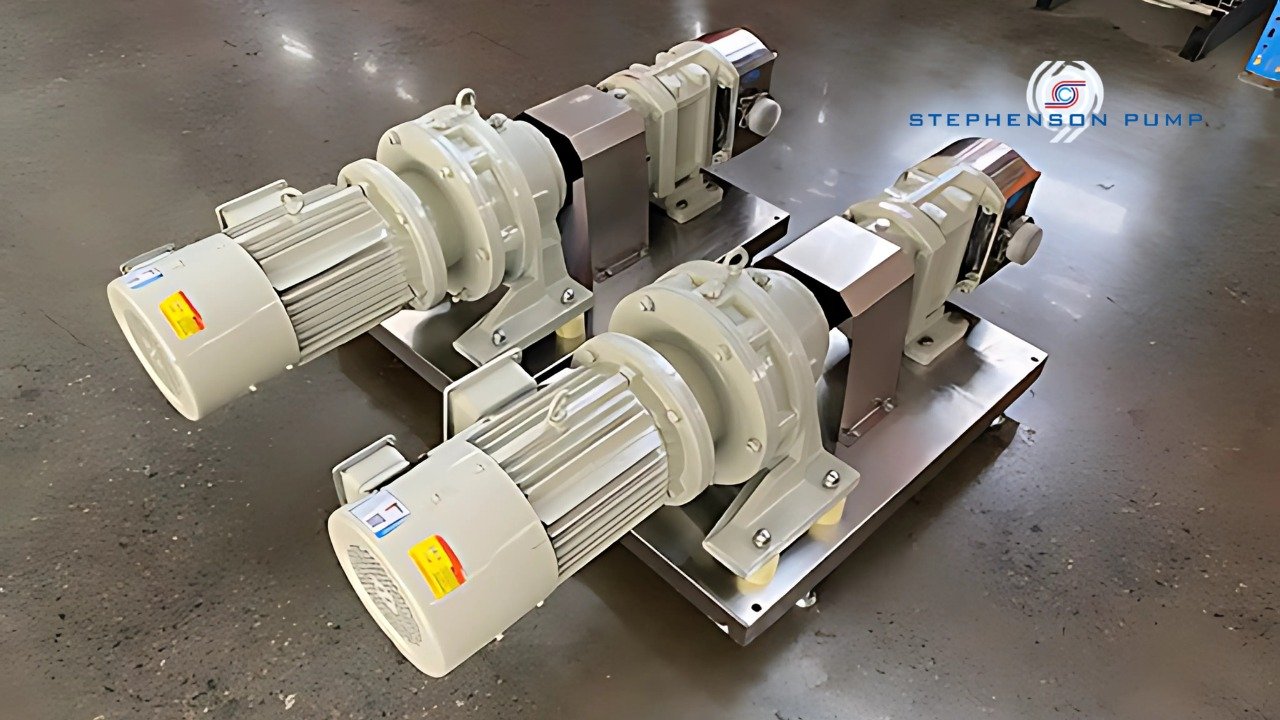

Case Study: Increasing Production Capacity with Rotary Lobe Pumps

A leading food processing company was experiencing difficulties with their existing pumping system, resulting in reduced production capacity and increased maintenance costs. The company’s production line was frequently shut down due to pump failures, resulting in lost productivity and revenue.

After installing Stephenson Pumps’ rotary lobe pumps, the company saw a significant increase in production capacity and a reduction in maintenance costs. The rotary lobe pumps provided gentle product handling, high efficiency, and ease of maintenance, resulting in:

– 25% Increase in Production Capacity*: The rotary lobe pumps enabled the company to increase its production capacity, meeting growing demand and reducing lead times.

– 30% Reduction in Maintenance Costs*: The rotary lobe pumps reduced maintenance costs by minimizing downtime and reducing the need for repairs.

Conclusion

Rotary lobe pumps are an excellent choice for food processing applications due to their gentle product handling, high efficiency, and ease of maintenance. Stephenson Pumps’ rotary lobe pumps can help food processing companies maximize efficiency and increase production capacity. Contact us to learn more about our rotary lobe pumps and how they can benefit your business.

FAQs

Q1: What are the benefits of using rotary lobe pump in food processing?

A1: Rotary lobe pump offer gentle product handling, high efficiency, and ease of maintenance, making them ideal for food processing applications.

Q2: What types of food products can be pumped using rotary lobe pumps?

A2: Rotary lobe pumps can handle a wide range of food products, including sauces, dressings, dairy products, beverages, and more.

Q3: How do rotary lobe pumps ensure product quality and safety?

A3: Rotary lobe pumps ensure product quality and safety by providing gentle product handling, minimizing shear and damage, and maintaining product integrity.

Q4: What materials are rotary lobe pumps made of?

A4: Rotary lobe pumps can be made of various materials, including stainless steel, cast iron, and other food-grade materials, ensuring compatibility with food products.

Q5: How often does a rotary lobe pump require maintenance?

A5: Rotary lobe pumps require regular maintenance, including routine inspections, lubrication, and replacement of worn parts, to ensure optimal performance and longevity.

Q6: Can rotary lobe pumps handle high-viscosity products?

A6: Yes, rotary lobe pumps are designed to handle high-viscosity products, making them suitable for a wide range of food processing applications.

3 Responses

Really appreciate your approach

This post filled my heart 💪 🌻 with hope and excitement for what lies ahead

Really love how you present information in such engaging ways